Zhongxin. com Shanghai News, January 9th (Sun Guogen, Chen Jing) What is a real smart hospital? What are the disadvantages of non-intelligent hospitals? How does artificial intelligence help hospital logistics management? How can technology make hospitals smarter? How can a smart hospital serve patients better and more accurately? On January 9th, at the 26th Shanghai Academic Salon of Hospital Logistics Dean, which was hosted by Fudan Hospital Logistics Management Research Institute and held in Shanghai Tenth People’s Hospital Clinical Science and Technology Innovation Park, with the theme of "Science and Technology Makes Hospital Logistics More Warm", logistics deans from major hospitals had a heated discussion on major issues of concern to these patients and citizens, and had their own views and practices.

Qin Huanlong, president of Shanghai Tenth People’s Hospital, experts from Shanghai Shen Kang Hospital Development Center and Shanghai Health Infrastructure Management Center, and logistics directors from 28 hospitals in Shanghai attended the salon.

Zhuge Lirong, dean of the Logistics Management Research Institute of Fudan Hospital, believes that in the past five years, in promoting the construction of smart hospitals, the pace of intelligent logistics has been significantly accelerated, and technology has made hospital logistics more temperature-oriented. He first introduced a set of data of Shanghai Tenth People’s Hospital with a history of 110 years with the topic of "Science and technology make hospital logistics more temperature": compared with 2015, the number of emergency patients increased by 18% in 2019, with 500,000 person-times; The number of discharged patients increased by 49%, with 36,000 person-times; The ratio increased by 49%, and the number of operations increased by 77%, reaching 33,000. Energy consumption decreased by 4.56 million yuan, and the energy consumption per 100 yuan of medical income was 1.07 yuan, a decrease of 0.14 yuan. This is the result of science and technology helping hospital logistics management. In 2020, it won the title of the sixth national civilized unit.

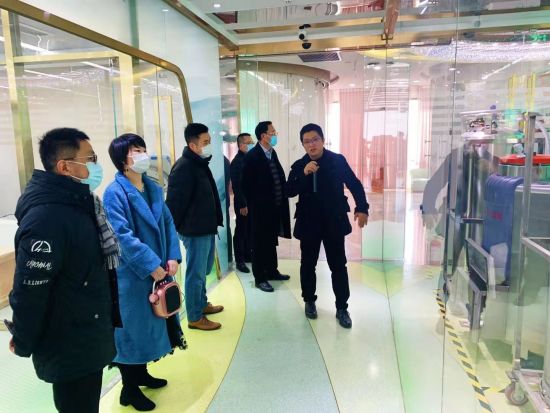

Intelligent logistics robots display their talents.

At the academic salon, Yang Xiaodong, vice president of Shanghai Children’s Hospital (Children’s Hospital Affiliated to Shanghai Jiaotong University), said in his keynote speech "Science and Technology Makes Hospital Logistics Smarter" that at present, the hospital has 2.47 million outpatient visits in 2019, 50,000 inpatients and 37,000 surgeries annually. In the past, the traditional manual transport mode in hospitals had some problems, such as low efficiency, high error rate, high transportation and management costs, high risk of safety and insecurity, randomness, mixed people and logistics, easy infection, environmental pollution and poor compliance. With the increasingly strict and standardized requirements of hospital logistics, the traditional human logistics mode will eventually be eliminated. Hospital logistics calls for major improvement of products and services.

Early pneumatic and rail logistics had high construction cost, difficult maintenance, low load capacity and high "paralysis" rate of single-line operation.

Later, the hospital changed to a mechanized logistics system, but there are still three major problems: high construction cost, insufficient load capacity, and simultaneous implementation in the planning of the new hospital building. Experts believe that in essence, this is a sacrifice of "high cost and low load" in exchange for the benefits compared with manual transportation.

Considering that the intelligent logistics robot has the advantages of real-time monitoring, whole-process monitoring, closed-loop management, log traceability (similar to blockchain), and automatic management of identity signing, for the sake of safety, it can also set operation permissions (different personnel have different operation permissions). Moreover, robots do not need talent, only need later training to master the work skills, and can do a lot of repetitive work without brains. The hospital decided to replace the existing mechanized logistics equipment with "intelligent logistics robots".

In June 2018, the hospital officially launched the "intelligent logistics robot" and introduced the fifth generation of "hospital logistics robot". When the first phase was accepted in September 2018, the robot distribution scope was on the 11th and 13th floors; In July 2019, the hospital successfully held the first national-level continuing education class of hospital logistics, "Application progress of artificial intelligence technology in logistics construction of smart hospitals"; In 2020, the hospital was upgraded and the latest version of the sixth generation was introduced to realize the closed-loop management of the whole process in the two business scenarios of PIVAS static drug transportation and general drug transportation; In May, 2020, the distribution scope of "Intelligent Logistics Robot" has reached the whole inpatient department when it was accepted in the second phase. During the epidemic, logistics robots played an important role in fever clinics. Nowadays, the robots in the hospital can automatically take the stairs, automatically cope with complex terrain, automatically climb hills, accurately locate themselves, avoid obstacles independently, and automatically open doors. In the hospital, you can see the spectacular scene of intelligent logistics robots queuing up for "work" every day.

According to statistics, since its 604-day operation, the "intelligent logistics robot" in our hospital has made 5393 trips, with 11508 delivery stations (with an average of 19.05 delivery stations per day), with a driving distance of 1251.40 kilometers and a delivery load of 156.3 tons. Each robot delivers an average of 10-15 trips per day, and each delivery is about 2-3 floors (covering 4-6 departments). The delivery time of each floor is about 15 minutes, and the single delivery weight is as high as 300 kg. Moreover, the robot is on call all day, the transportation data is recorded in real time, the transportation position is displayed in real time, and the operator signs for the record to ensure safety. The standard process effectively reduces the contradiction between departments, reduces the cost of human resources, improves the productivity of the hospital by 20%-30%, and reduces the management risk.

Independent research and development of three generations of intelligent insulation food delivery vehicles is favored.

Shi Wei, deputy general manager of Shanghai Fudan Luyuan Biomedical Technology Co., Ltd., confirmed with facts in his keynote speech that technology can empower catering and nutrition can help rehabilitation. According to the survey, 30%-70% patients gave up because the meals provided by the hospital were "not appetizing" and chose to solve them themselves. But a warm and nutritious meal can help patients recover as soon as possible. They have put a lot of brains into the application of electric heating and insulation food delivery vehicles to serve patients. Nowadays, Shanghai hospitals generally use imported second-generation electric heating and insulation food delivery vehicles, which only have insulation function, and each needs 40 thousand yuan; The third-generation insulated food delivery truck made of stainless steel antibacterial materials independently developed by Fudan Luyuan has the functions of electric heating, ultraviolet disinfection and electric power assistance, and only costs 30,000 yuan. Science and technology+humanities, with a warm diet, is not only beneficial to hospitalized patients, but also won the praise of operating room, ICU staff and overtime doctors. The small electric heating and insulation food delivery car embodies the empowerment of science and technology and valuable humanistic care. At present, Fudan Luyuan also provides on-site maintenance for the second-generation food delivery trucks in major hospitals for 3-4 times every year, effectively prolonging the service life. Thanks to the excellent maintenance service, the service life of 521 second-generation electric heating and insulation food delivery vehicles in 35 hospitals in Shanghai, including Zhongshan, Huashan, Jiuyuan, Tumour and Huadong, has been greatly prolonged, of which 46 in Huashan Hospital have been used for 13 years, 44 in Zhongshan Hospital for 12 years and those in other hospitals such as Jiuyuan Hospital for more than 10 years.

During the salon, the reporter saw that the brainstorming hosted by Luo Meng, executive deputy secretary of the Party Committee of the Ninth People’s Hospital affiliated to Shanghai Jiaotong University School of Medicine and executive vice president of Fudan Hospital Logistics Management Research Institute, was quite interesting. Under his auspices, Zhu Yongsong, Zhu Jiong, Yang Xiaodong, Wang Zhenrong, Liu Jun and Fang Qiang, logistics deans from major hospitals in Shanghai, took the topic of "Should the future development of hospital logistics pay more attention to the flow of science and technology or the flow of humanity?" The two sides focused on the practical application and prospect of artificial intelligence technology in the medical field and the development of science and technology to a certain stage, and the patients’ demand for humanistic care and quality of life was increasing, focusing on the key words "application, efficiency, experience and life.

The Academic Salon of Hospital Logistics Dean sponsored by Fudan Hospital Logistics Management Research Institute was founded in March 2011 and held for three times a year, and has been held for 26 times so far. As a platform for major hospitals in Shanghai to build information sharing among hospital logistics managers, each salon focuses on a hot and difficult issue in the field of hospital logistics management to discuss, discuss and debate, which has a positive effect on further broadening the horizons of hospital logistics managers and has an important impact on hospitals across the country, and has become a beautiful business card in Shanghai.

Note: please be sure to indicate the source when reprinting the content of the article!

Editor: Chen Jing